Dip-tech

Our story began over 17 years ago when a focused team of visionary entrepreneurs, seasoned industry experts and leading academics came together with a bold objective: to digitalize the ancient endeavor of printing on glass

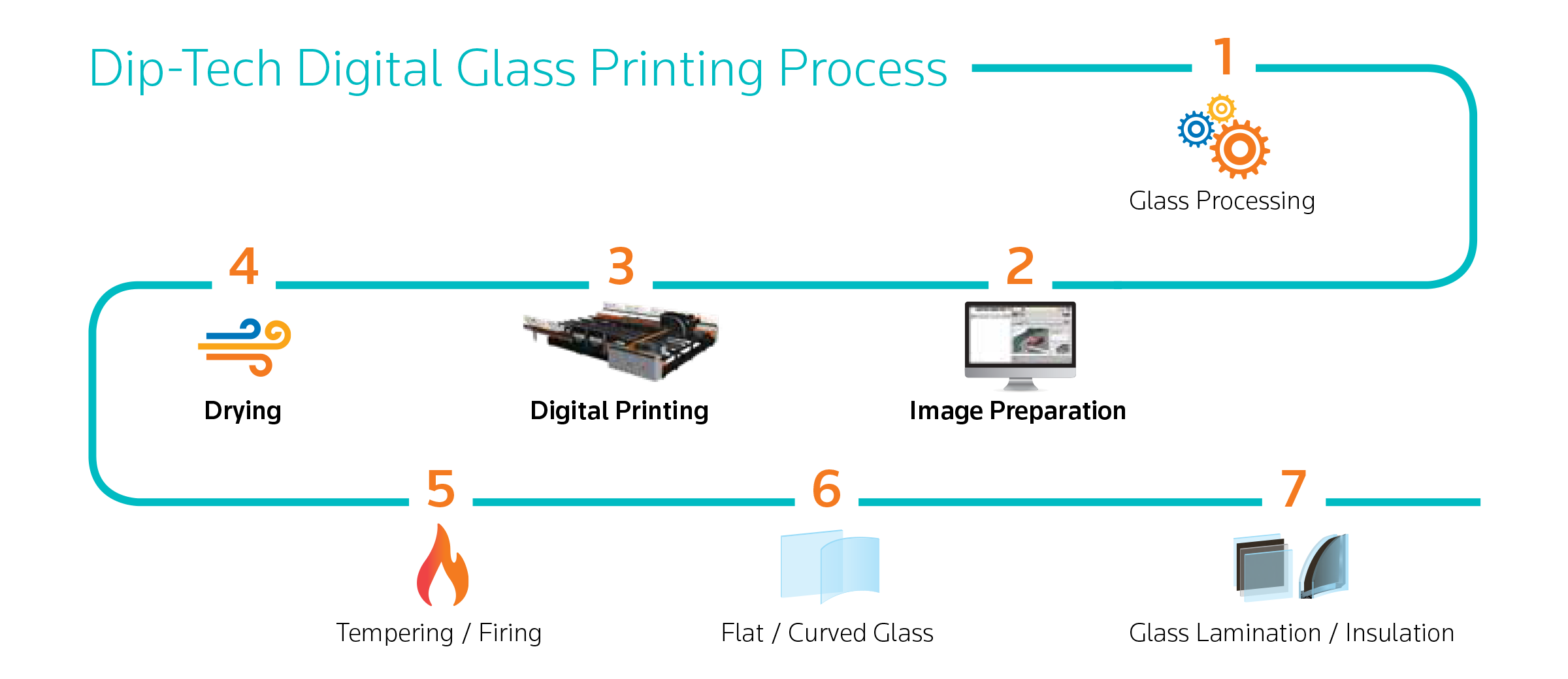

Within a few years we developed our first digital printers and ceramic inks based on patented technologies, basically creating the digital glass printing industry. Initially targeting glass processors in the automotive sector, we expanded our solutions to also serve the architecture, appliance and dinnerware markets.

Over the years we became the first company to deliver a complete offering for digital printing featuring specialized digital printers, vividly colored ceramic inks, cutting-edge software and worldwide support. We have established ourselves as the market and innovation leader with some 350 state-of-the-art digital printers installed across the globe.

Rediscover Digital Glass Printing

- Exceptional jetting capacity

- 12 color system for maximum versality

- Split conveyor system for optimal productivity

- Autonomous quality consistency system

- Print heads quality inspection

- Automatic glass scanning

- Zero ink disposal

- Zero wash

- Zero purge

- Automatic orifice wiping system

- User friendly-fast and easy access for maintenance and diagnostics

- Automatic Backup and notification system

Fast, smart and robust

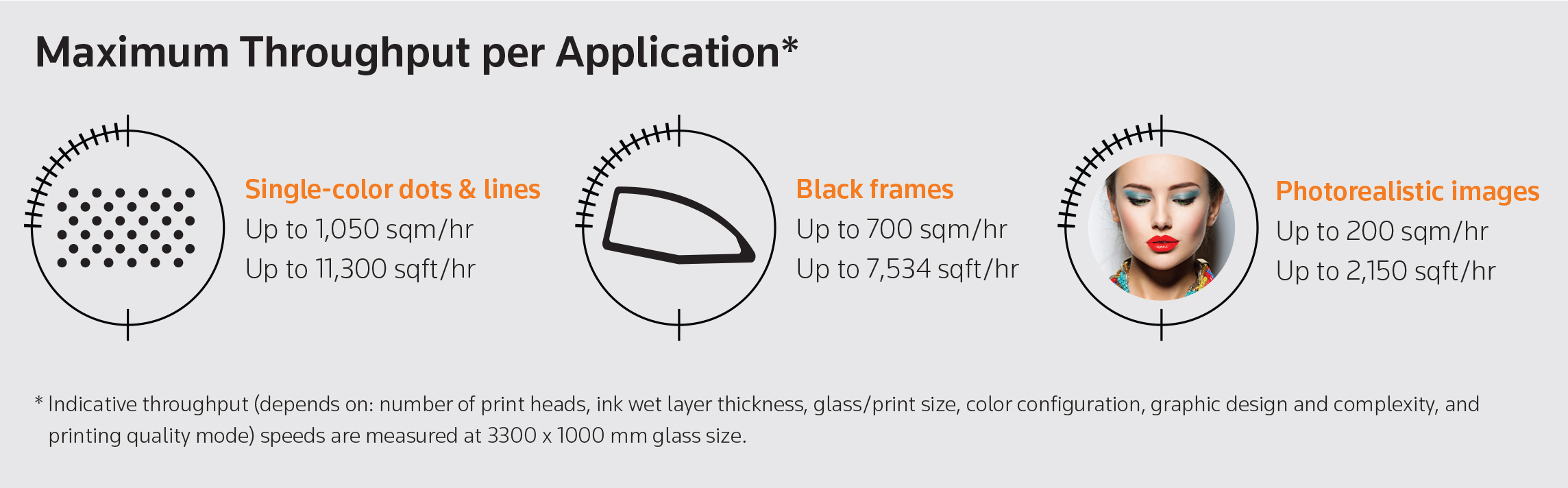

A powerful and easy-to-use machine that provides record-breaking printing speed and quality and sets a new standard for digital glass printers

Best-in-class print heads, empowered electronics, innovative software and an all-new ink system design come together to provide extraordinary speed and quality.

Save time and enhance printing consistency and realiability with a system that combines automatic machine calibration, nozzle performance inspection, nozzle compensation.

Automatically scan and correct image position on any glass to ensure perfectly seamless multi-panel designs.

Constant monitoring of print heads and glass temperature for continuous control of printing quality.

KEY SPECIFICATION

| Machine configuration | Premuim | Express | High Press | Press |

|---|---|

| Maximum glass size | Width:2,800-3,300 mm, 110-130 in | Length: 2,600-18,000 mm, 102-720 in |

| Minimum glass size | 400x400mm* | 16x16in* |

| Printing resolution | Real - up to 720DPI | Apparent - above 2,800DPI |

| Drop size | 12pl/variable drop size |

| Number of ink channels | Up to 12 |

| Glass thickness | 2-19 mm 0.1 - 0.75 in |

| Inks | Dip-Tech SPECTRUM R Inks, Dip-Tech Extra Durable S1 Inks, Dip-Tech Digital conductive Ink, Dip-tech Previous Metal Inks |

| Empower drop-fixation | Included |

| Software | DXP4 Advanced (includes RIP, Pattern Generator, CMiX) |

| Inline pass through conveyor | Included/Split conveyor (optional) |

| Image format | All popular graphic formats, including PDF, PS, EPS, Tiff, BMP, JPEG |

| Ambient temperature | 18-25°C /64-77°F |

| Power input | 3x32A/3x125A (Integrated dryer) |

| Overall dimensions L x W x H | 4 meters:7,433x6,403x2,750 mm, 292x252x108 in 6 meters: 9,673x6,403x2,750 mm, 292x252x108 in |

Production Versatility

Endless color configurations and fast, economical, and automatic color changeover.

Available for Different Glass Lengths, from 2.6 to 18 Meters and More