Founded in 1870, Glaston celebrates its 150 years anniversary in 2020: from a forest company to world’s leading glass processing technology company.

Glaston is the glass processing industry’s innovative technology leader supplying equipment, services, and solutions to the architectural, automotive, solar, and appliance industries. The company also supports the development of new technologies integrating intelligence to glass.

Glaston is committed to providing its clients with both the best know-how and the latest technologies in glass processing, with the purpose of building a better tomorrow through safer, smarter, and more energy-efficient glass solutions. Glaston operates globally with manufacturing, services and sales offices in 10 countries and its shares (GLA1V) are listed on NASDAQ Helsinki Ltd.” Unquote

Our mission is to make your glass outstanding

By providing you with machinery, technology and expertise so you can truly stand out. We are committed to helping you achieve success in your chosen area of glass processing.

We’re passionate about innovating the next level in world-class technology, dedicated services and technical support, so you get the highest production energy efficiency and best end glass quality. We offer you our expertise to inspire potential and open up exciting opportunities in glass.

Products

Main Dimensions

| GLASTON RC SERIES | FOOTPRINT Length x width (mm) |

HEIGHT (mm) | LOADING AREA width x length (mm) |

MIN. GLASS SIZE width x length (mm) |

|---|---|---|---|---|

| 1530 | 15 600 x 5 000 | 3 300 | 1500 x 3000 | 200 x 450 (100 x 250) |

| 2136 | 18 000 x 5 400 | 3300 | 2100 x 3600 | 200 x 450 (100 x 250) |

| 2436 | 18 000 x 5 900 | 3300 | 2400 x 3600 | 200 x 450 (100 x 250) |

| 2448 | 22 800 x 5 900 | 3300 | 2400 x 4800 | 200 x 450 (100 x 250) |

| 2848 | 22 800 x 6 300 | 3300 | 2800 x 4800 | 100 x 250 |

| 2860 | 28 000 x 6 300 | 3300 | 2800 x 6000 | 100 x 250 |

| 3360 | 28 000 x 6 800 | 3300 | 3300 x 6000 | 100 x 350 |

Technical Capabilities

| Capacity (loads/hour) Clear glass (0,04) | Capacity (loads/hour) Low-E glass (0,04) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GLASTON RC SERIES | 3 mm* | 4 mm | 5 mm | 6 mm | 8 mm | 10 mm | 12 mm | 15 mm | 19 mm | 3 mm | 4 mm | 5 mm | 6 mm | 8 mm | 10 mm |

| 1530-2448 | 25 | 20 | 16 | 14 | 10 | 8 | 6 | 4 | 3 | 16 | 13 | 11 | 9 | 6 | 5 |

| 1530-2448 - BBP | 25 | 24 | 19 | 16 | 12 | 9 | 6 | 4 | 3 | 19 | 16 | 13 | 10 | 8 | 6 |

| 2848-3360 | 25 | 22 | 18 | 15 | 11 | 9 | 6 | 4 | 3 | 18 | 15 | 12 | 10 | 7 | 6 |

| 2848-3360 - BPP | 25 | 24 | 19 | 16 | 12 | 9 | 6 | 4 | 3 | 19 | 16 | 13 | 10 | 8 | 6 |

Note: Capacities are based on 65% loading efficiency and with glass size 865 x 1930 mm according to EN 12150 and ANSI Z97.1 standards. Final capacity depends on glass size, shape, and edgework quality.

*3mm capacity depends on the blower/compressor combination.

| GLASTON RC SERIES | Heating & Drives | Installed power (kW) blowers** |

Total | Average process powe*** kVA |

|---|---|---|---|---|

| 1530 | 315 (360) | 1 x 250 | 565 (610) | 201 (242) |

| 2136 | 496 (565) | 1 x 315 | 811 (880) | 325 |

| 2436 | 580 (611) | 1 x 315 | 895 (976) | 376 (441) |

| 2448 | 726 (828) | 1 x 315 | 1041 (1143) | 489 (570) |

| 2848 | 854 | 2 x 250 | 1354 | 606 (659) |

| 2860 | 1044 | 2 x 250 | 1544 | 719 (806) |

| 3360 | 1234 | 2 x 315 | 1864 | 828 (903) |

Power information with performance package (BPP) is stated in brackets.

**Blower powers are based on 3,8 mm tempering capacity according to EN 12150 and ANSI Z97.1 standards.

***Average process power calculated with 4mm clear glass, 65% loading utilization according to EN 12150 standard.

Energy Consumption

| GLASTON RC SERIES | LEAR FLOAT GLASS kWh/m2 |

LOW-E GLASS (0.04) kWh/m2 |

|---|---|---|

| 4 mm | 2.9 | 3.5 |

| 6 mm | 3.8 | 4.5 |

| 10 mm | 6.0 | 7.0 |

Energy consumption values given with 65% loading efficiency with an ambient temperature of 25°C according to EN 12150 standard. Values are based on continuous production figures with RC Series 2860 machine with performance package (BPP).

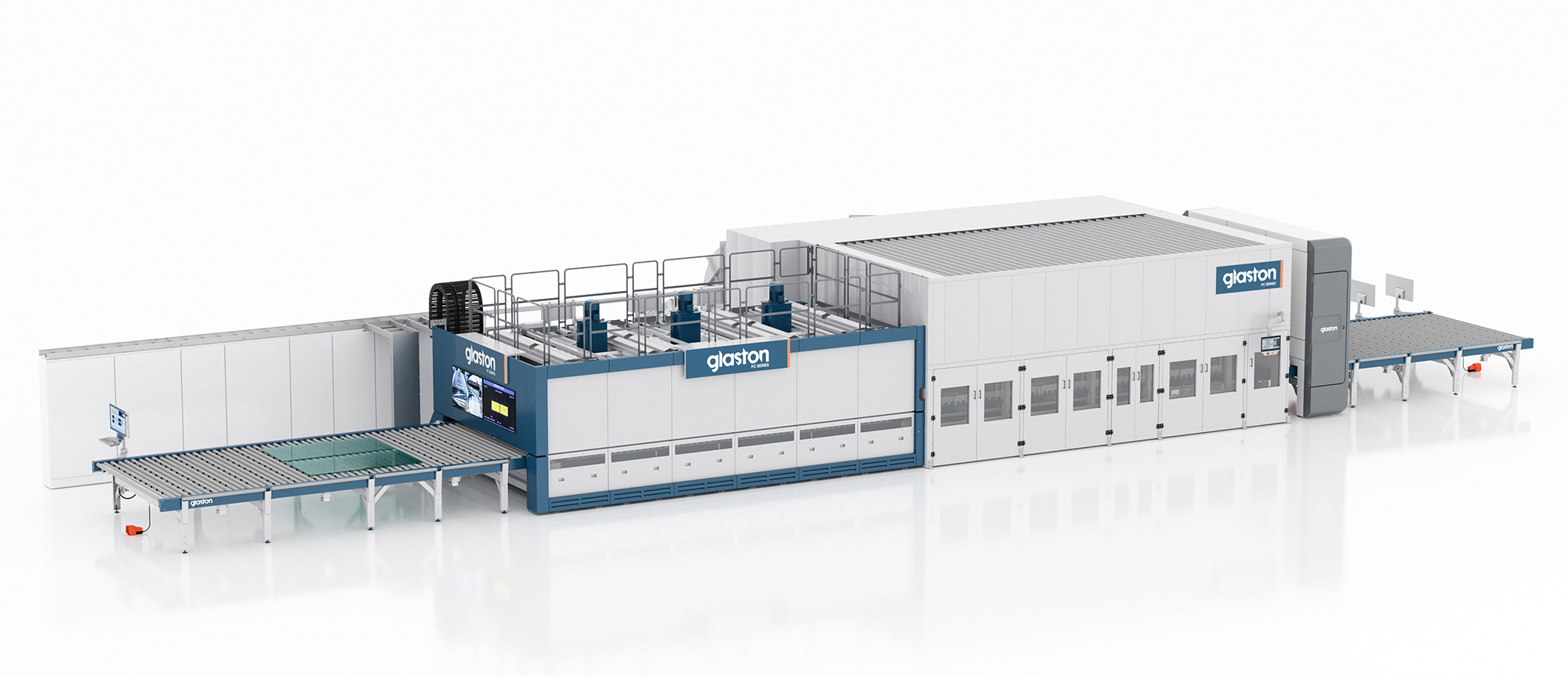

Main Dimensions

| GLASTON FC SERIES | FOOTPRINT Length x width (mm) |

HEIGHT (mm) | MAX. GLASS SIZE width x length (mm) |

|---|---|---|---|

| 2136 | 18 000 x 6 300 | 3 400 | 2100 x 3600 |

| 2142 | 18 000 x 6 300 | 3 400 | 2100 x 4200 |

| 2436 | 18 000 x 6 600 | 3 400 | 2400 x 3600 |

| 2448 | 22 800 x 6 600 | 3 400 | 2400 x 4800 |

| 2848 | 22 800 x 7 000 | 3 400 | 2800 x 4800 |

| 2860 | 27 800 x 7 000 | 3 400 | 2800 x 6000 |

Technical Capabilites

| Capacity based on glass thickness for clear float glass (loads/h) |

Capacity based on glass thickness for Low-E glass 0,02 (loads/hour) |

||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GLASTON FC SERIES | 3 mm* | 4 mm | 4 mm | 6 mm | 8 mm | 10 mm | 12 mm | 15 mm | 19 mm | 3 mm | 4 mm | 5 mm | 6 mm | 8 mm | 10 mm |

| Chinook | 25 | 24 | 19 | 16 | 12 | 9 | 7 | 5 | 3 | 23 | 19 | 15 | 13 | 9 | 7 |

| Chinook Pro | 25 | 24 | 20 | 17 | 12 | 10 | 7 | 5 | 3 | 24 | 20 | 16 | 13 | 10 | 8 |

Vortex Pro capability option is available for both Chinook and Chinook Pro versions.

Note: Capacities are based on 65% loading efficiency and with glass size 865 mm x 1930 mm according to EN 12150 and ANSI Z97.1 standards.

Final capacity depends on glass size, shape and edgework quality.

* The capacity for 3 mm glass tempering depends on the blower/compressor configuration.

| GLASTON FC SERIES Type | Heating & Drives | Installed power (kW) Quench blowers1) |

Total | Average process power** kVA |

|---|---|---|---|---|

| FC Series 2136 | 694 [818] | 2 x 250 (500) | 1194 [1318] | 380 [366] |

| FC Series 2448 | 1057 [1228] | 2 x 250 (500) | 1557 [1728] | 540 [528] |

| FC Series 2848 | 1161 [1347] | 2 x 315 (630) | 1791 [1977] | 613 [604] |

| FC Series 2860 | 1421 [1666] | 2 x 315 (630) | 2051 [2296] | 752 [732] |

Power information for FC Series with Chinook Pro is stated in brackets.

1) Blower powers are based on 3.8 mm tempering capability according to ANSI Z97.1 and EN 12150 standards.

The average process power is calculated for 4 mm clear glass tempering with 65% loading efficiency according to EN 12150 standard.

Energy Consumption

| GLASTON FC SERIES | Glass thickness (mm) |

Energy consumption (kWh/m2) clear float glass | Energy consumption (kWh/m2) Low-E glass (0,02) |

|---|---|---|---|

| Chinook | 4 | 2.8 | 3.3 |

| 6 | 3.5 | 3.8 | |

| 10 | 5.6 | 5.9 | |

| Chinook Pro | 4 | 2.7 | 3.1 |

| 6 | 3.3 | 3.5 | |

| 10 | 5.2 | 5.4 |

Energy consumption values are given with 65% loading efficiency and an ambient temperature of 25 °C according to EN 12150 standard. Values are based on continuous tempering production with FC Series 2448 and FC Series 2448-Chinook Pro.

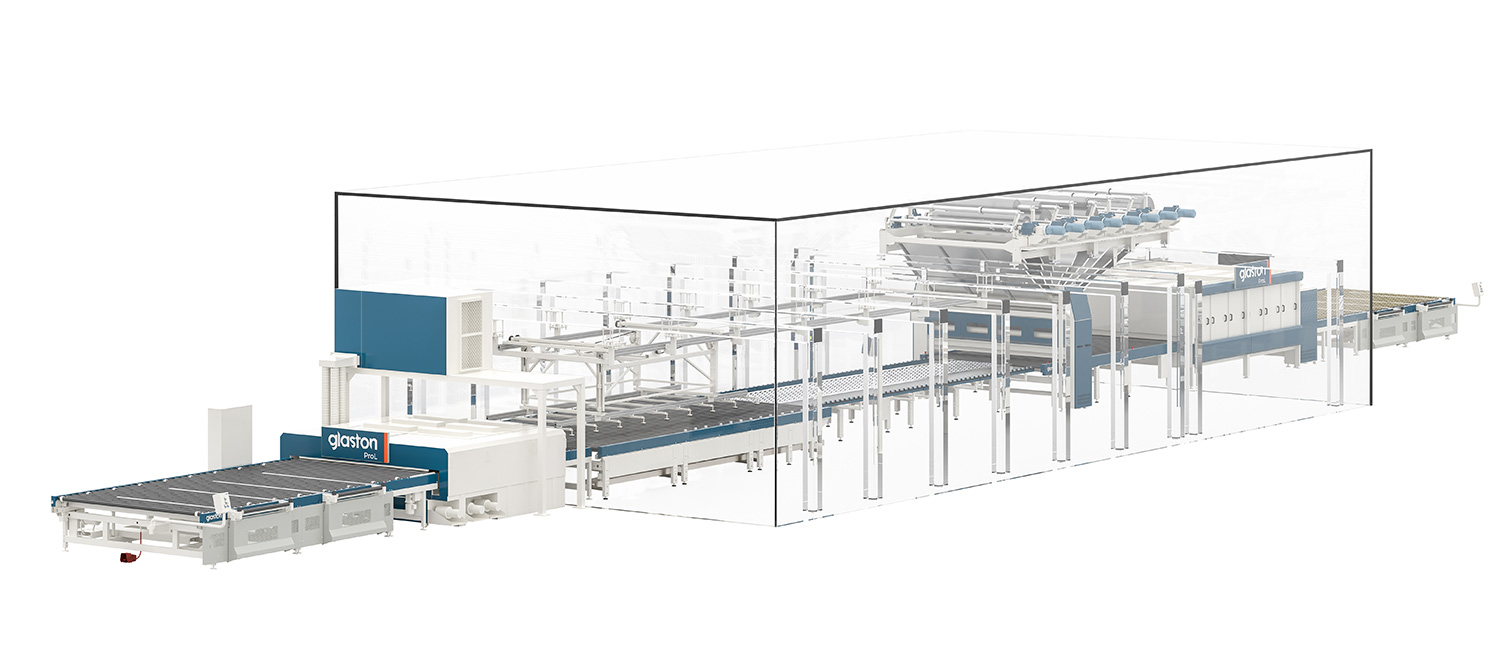

Main Dimensions

| Glaston ProL™ | Footprint WxL (m) | Height (m) | Laminating room example (m) | Installed power |

|---|---|---|---|---|

| ProL™ 2636 | approx. 33 x 7 | 4.2 | 9 x 10 x 4.2 | 184 |

| ProL™ 2648 | approx. 36 x 7 | 4.2 | 11 x 10 x 4.2 | 184 |

| ProL™ 3360 | approx. 42 x 8 | 4.2 | 14 x 12 x 4.2 | 235 |

Technical Capabilites

| Line speed (m/min) | ||||

|---|---|---|---|---|

| Operating mode | Laminate type | 1 chamber furnace | 2 chamber furnace | 3 chamber furnace |

| Continous with small glass sizes |

3/3/1 | 2.3 | 4.5 | 6.7 |

| 4/4/1 | 1.7 | 3.3 | 4.9 | |

| 6/6/1 | 1.0 | 2.0 | 3.0 | |

| Capacity* pcs/h (m2/h) | ||||

|---|---|---|---|---|

| Operating mode | Laminate type | 1 chamber furnace | 2 chamber furnace | 3 chamber furnace |

| Sheet-by-sheet with large glass sizes (e.g 2500 x 3000 mm) |

3/3/1 | 26(195) | 34(255) | 34(255) |

| 6/6/1 | 13(98) | 24(180) | 33(248) | |

| 10/10/1 | 8(60) | 15(113) | 21(158) | |

Main Components

| LT | Loading table with side rolls |

|---|---|

| WM | High-speed washing machine for normal soft-coated glass |

| GAL | Glass Assembly lifter |

| AC | Assembly conveyor |

| TC | Trimming conveyor |

| PRM-2 | PVB roll magazine for motorized unwinding of PVB |

| LF-1C | Pre-pressing unit with convection heating |

| UT | Unloading table with side rolls |

Optional Features

| LF-2C | Heating chamber extension for increased capacity |

|---|---|

| LF-3C | |

| PRM-4 | PVB roll magazine extension for additional PVB rolls up to 8 rolls |

| PRM-6 | |

| PRM-8 | |

| TLT | Tilting loading table |

| TUT | Tilting unloading table |

| CARE | Glaston Care service agreement with ROLS remote online service |

| TURNKEY | Turnkey installation |

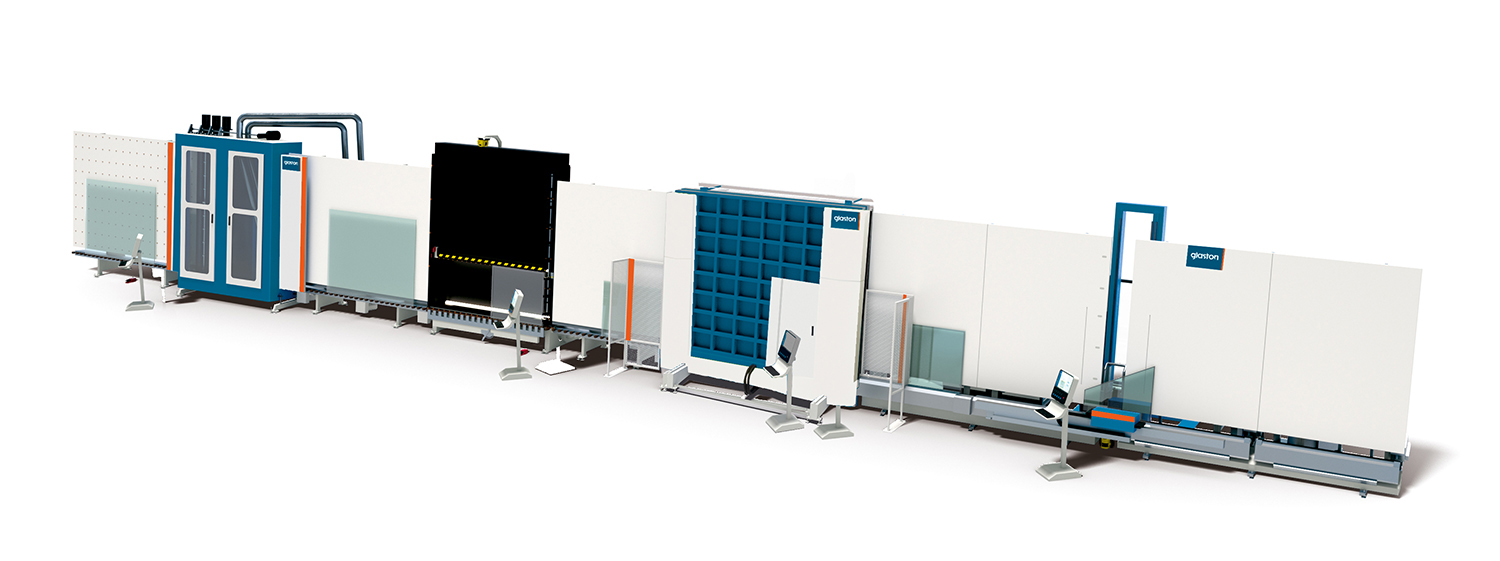

Compact. Your entry into the world of I.G. Manufacturing.

The start-up solution in automated insulating glass production

The Glaston COMPACT BOX provides high quality I.G. unit manufacturing with an excellent cost/performance ratio. In addition to the proven quality and reliability, this I.G. line offers real added value

• Low investment costs

• A compact line layout

• Diverse options

Efficient. Fully equipped I.G. Manufacturing.

The Glaston COMFORT BOX offers high quality, gas filled I.G. unit manufacturing of rectangular and shaped formats. This I.G. line offers numerous components as standard e.g.

• Air cushion conveyors

• Production of 3-sided stepped I.G. units

Precise. I.G. Manufacturing for the toughest demands.

The system solution for insulating glass using aluminum, stainless steel or plastic spacers

The I.G. line Glaston VARIO BOX is an individually configurable production line for insulating glass unit manufacturing using conventional spacers.

• High flexibility and excellent productivity

• Premium component quality

• Long service life

• Multiple line expansion options

Rigid Lifts

The EASY’LIFTER simplifies glass handling thanks to its low dead weight and rigid load guidance – available in many versions

Manipulators

Vacuum hoists that can be used flexibly are particularly suitable for use in chain hoists, cable hoists or hall cranes

(Battery-powered) Suction Frames

The glass suction devices are ideal for the vertical handling of glass and are also available in a battery-powered version for mobile use

Slewing Cranes and Craneways

Our X-Y lightweight craneways and slewing cranes are the optimal addition to your glass manufacturing. Due to the modular construction system we can provide on-site response regarding your individual space requirements