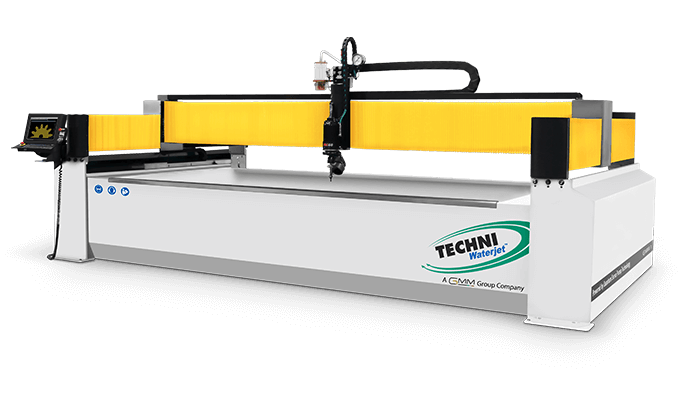

TechniWaterjet™ is your trusted partner when it comes to giving your business a competitive advantage using finest abrasive Waterjet machines and cutting technology. Our team of water jet machine engineers has been developing and innovating new complete high-pressure abrasive waterjet cutting solutions for over 30 years.

We pride ourselves on working closely with your business to identify your challenges and provide you with the ultimate water jet cutter for your application.

Our highly trained sales team will offer you the support and machinery you need to ensure your success in generating a high return on your investment.

Products

BREAK AWAY HEAD

Should the cutting head inadvertently crash into a clamp/fixture, hit the edge of a work piece or an upturned part, the Break Away Head will detect the crash and automatically stop the machine. Its precision tolerance and design ensures the crash recovery and return the exact previous position is easy.

SERVO Z AXIS

Servo Z axis with auto height position recall, laser terrain mapping (additional) and edge location optics.

WATER RAISE AND LOWER

Water Raise & Lower at the push of a button for quieter, cleaner and safer submerged cutting; our tanks include air-light welds of an air chamber which uses regular shop air pressure to raise or lower the water level. No moving parts are required, an on/off solenoid valve allows water level adjustment with a few seconds.

VARIABLE FEEDER AND TECH-SENSE

The Tech-Sense Monitoring System enables true unattended operations. Should the cutting be disrupted, e.g. blocked nozzle, the machine will pause the program which can be easily resumed. With a new Variable Abrasive Feeder, garnet supply to the machine is automatically adjusted by the software.

ABRASIVE PUMP AND HOPER

The hinged lid on the hopper system allowseasy access to inspect the fill at any time, without the need to de-pressurize. The clear pump chamber allows a quick visual to ensure abrasive is pressurized, allowing the hopper lid to be opened at any time.

REMOTE CONTROL PENDANT

The MPG gives full logging control in X-Y & Z allowing to manually wind forward or backward through a cutting path. This enables the operator to find the exact point from which to restart cutting after a stoppage, or simply locate a pre-cut part.

LASER MAPPING

The Laser performs a precise mapping of the workpiece to increase the accuracy of the cut. It's able to map pierce points, the full sheet, and paths, as well as find origin and edges of te sheet

TOUCH-PROBE

Touch-Probe performs terrain mapping by touching the surface of the slab. This allows the cutting head to automatically adjust its standoff.

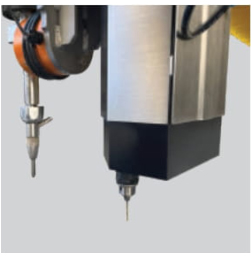

DRILLING HEAD

Drilling Head avoid delamination or cracking of materials such as composites and laminated by drilling a small hole instead of using the cutting head for the piercing process.

DUAL HEAD CUTTING

Twin cutting heads increase the productivity. The machine will run the program once but twice the amount of parts are being cut. Pump power is a key decision variable when considering the option.

GARNET REMOVAL SYSTEM

The GRS collects used abrasive accumulated in the bottom of the Waterjet tank. The abrasive is pumped to the GRS where it settles into a bag while the water is returned tot he waterjet tank.

SAFETY BARRIERS

Two options are available:1-Sliding Safety Gate with polycarbonate windows. 2-Safety Light Curtain instrusion sensor. Both options include side and rear fencing.

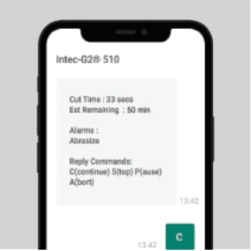

OFFSITE SMS NOTIFICATION

The Offsite Notification can be very useful with long programs and lights out operation. The machine can send a text message if an alarm complete. You can then send a text message back to tell the machine to continue, to abort the program or to simply ask information.

LINEAR SCALE FEEDBACK / TRASOUTORE DI POSIZIONE A BANDA MAGNETICA

The Linear Scale Feedback is what makes the highest tolerances possible. By mapping the entire cutting area with a laser-calibrated digital interferometer, the motion system can deliver positional accuracy of 0.05 mm(0.002"). Repeatability of motion is increased to 0.025 mm (0.001").